Blichmann Hellfire Burner

Related Products

1/2" Auto-Siphon

$ 19.25

26" long 1/2" auto-siphon by Fermtech. Quickly and easily transfers liquids twice as fast as a 3/8" racking cane. Includes 6 feet of 1/2" vinyl tubing. Auto siphon clamp sold separately.

12" Laboratory Thermometer

$ 7.00

If you're looking for a near-instant temperature reading, this laboratory thermometer is the way to go. Has an eye hole at the top for running string through if desired. Range 0- 220F; 0-120C.

24" Steel Spoon

$ 9.00

Perfect spoon for stirring wort or mash. You could also use it to eat cereal, but that might be just a little absurd.

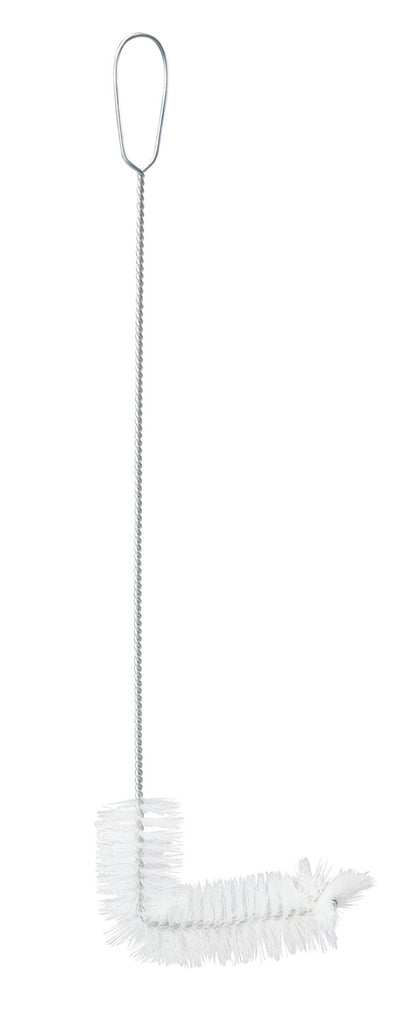

30" Carboy Brush

$ 7.75

Team me up with a good cleaner like PBW and we'll make cleaning that carboy a breeze.

6.5 Gallon Bottling Bucket

$ 22.00

This bottling bucket includes a ported spigot with two gaskets. Makes bottling easy, especially when coupled with our filler wands. Lid sold separately.

6.5 Gallon Plastic Fermenting Bucket

$ 24.50

Food grade fermenting bucket with graduated markings showing volume. Includes a drilled/grommeted lid.

7.9 Gallon Plastic Fermenting Bucket

$ 33.50

Food grade bucket with graduated markings showing volume. Includes drilled/grommeted lid.

Acid Blend (2 oz.)

$ 3.50

Used in wine must preparation for pH adjustment. Can also be added later for balance against overly sweet wine.

Airlock

$ 2.00

Used to allow CO2 release, while preventing oxygen intrusion. Two styles available.

Amylase Enzyme (1 oz.)

$ 2.25

Improves starch-to sugar conversion; increases alcohol yield and reduces residual gravity.

Apple Cider Kit

$ 43.00

A traditional hard sparkling cider that is packed full of flavor. This apple cider is crisp, light and refreshing, a perfect choice any time of the year. Don't forget the 2lbs of sugar you'll add! Our corn sugar is perfect. ABV: 5.2 Color: Golden Apple Cider Instructions

Beer Wine Refractometer with ATC

$ 48.00

Refractometers accurately measure sugar concentration in watery solutions using only a small sample, making them a convenient alternative to hydrometers that need several ounces of liquid and a test tube. This model includes Automatic Temperature Correction and displays readings on both Brix and Specific Gravity scales. It's ideal for assessing ...